CNC machine tools after decades of development, derived a variety of different CNC equipment, each equipment has a variety of differences in structure, design and performance.

CNC machine tools after decades of development, derived a variety of different CNC equipment, each equipment has a variety of differences in structure, design and performance.

The price of machinery and equipment has been a concern of enterprises. Vertical machining centers can complete milling, boring, drilling, tapping and cutting threads and other processes have received many enterprises.

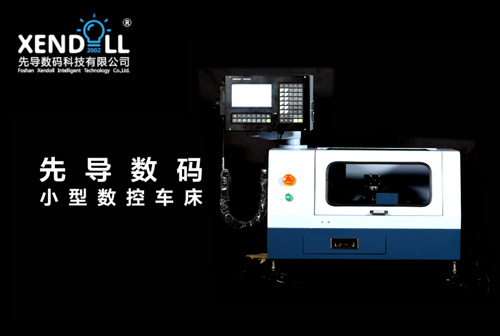

Small CNC lathe in use for a period of time, in order to better complete the processing, to often maintain, so what is the small CNC lathe to replace the row tool?

Too large or too small radial and axial clearance of CNC machine tool spindle bearings are the main causes of CNC machine tool failures.

When it is difficult to determine what kind of fault occurs in the machine tool, replacement comparison method can be used to determine, the difference is the fault of the machine tool.

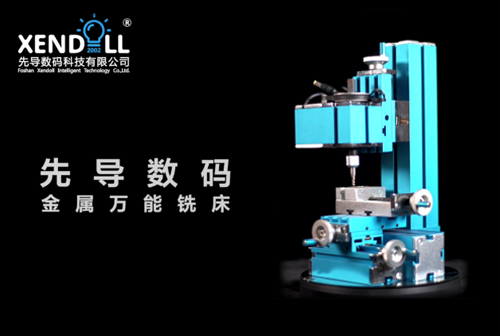

Small drilling and milling machine processing aluminum alloy products using white steel or alloy milling cutter can be. The drill chuck is used to hold the drill bit for drilling, and the contour and plane are milling with the elastic chuck mounting cutter.

1. High-speed steel;

High-speed steel with CNC lathe parameters refers to high-alloy tool steel containing more alloying elements such as tungsten, chromium, molybdenum, and vanadium. High-speed steel can be divided into ordinary high-speed steel and high-performance high-speed steel according to different uses.

Nowadays, CNC machining plays a leading role in the manufacturing industry, thus affecting social development. However, when the CNC lathe fails, the operator should stop the machine tool and keep the scene

Small CNC lathes are widely used in the power equipment manufacturing industry. The energy issue is a national strategic issue, and my country has always paid attention to the manufacture of power equipment.

The milling cutter of the small milling machine is usually the main movement of rotation, and the movement of the workpiece (and) the milling cutter is the feed movement. It can process planes, grooves, and various curved surfaces, gears, etc.

The voltage across the motor multiplied by the current flowing through the motor does not equal the output power. Output power is the power value at which the motor converts electrical energy into mechanical energy. Since electric motors cannot completely convert electrical energy into mechanical energy, due to the actual coil resistance,

The small production machine tools referred to here include miniaturized CNC lathes, CNC milling machines, machining centers, engraving machines and ordinary lathes, milling machines and compound machine tools, etc.