The main difference between machine tools and other machines is that machine tools are machines that make the machine itself, so machine tools are also called "industrial machine tools".

The main difference between machine tools and other machines is that machine tools are machines that make the machine itself, so machine tools are also called "industrial machine tools".

In recent years, our information technology level continuously improves, has obtained an all-round development, prompting all walks of life to further develop, especially the electromechanical numerical control technology and equipment.

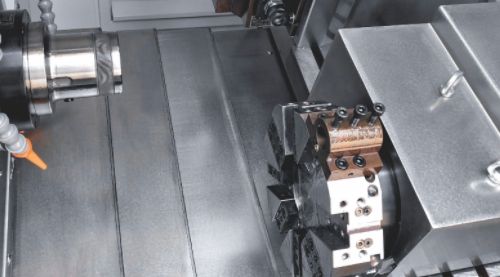

Machine tool movement is the clearance, including the guide rod driving tool holder movement. Long time will wear, there will be too much gap, affecting the processing data. Let's talk about the causes and effects of CNC lathe clearance.

Since its inception, CNC machine tools have appeared on the tables of many makers' LABS in primary and secondary schools, enabling countless small makers to turn their ideas into reality.

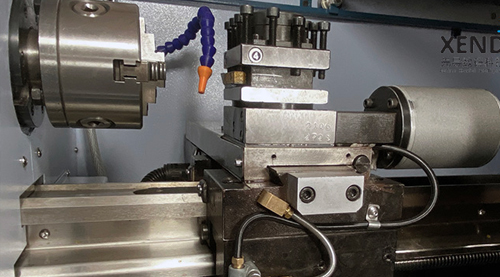

CNC machine tools can be processed normally. In addition to machine tool hardware and system software, the heaviest tool is CNC tool. CNC tool is an important tool for machining production and cutting of machine tools, including blade, grinding tool, tool bar, tool handle, etc.

When assembling CNC machine bearings, the contact Angle and precision of CNC machine bearings play a very important role. Therefore, when installing bearings, it is necessary to ensure that the contact Angle is qualified, but also to ensure that the actual width of angular contact ball bearing meets the regulations.

Maintenance and maintenance of machinery and equipment is very important during the rainy season, because in such weather, equipment is more likely to break down, and many parts of the south of the country have heavy rainfall and even floods in some areas.

Precision, as one of the main features of machine tool that is different from other machines, has been the unremitting pursuit of the global machine tool industry. In the era of micro and nano, the intelligent technology of machine tool industry is now fruitful in application.

Numerical control lathe can process parts with small surface roughness, not only because of the rigidity of the machine tool and high manufacturing accuracy, but also because it has constant linear velocity cutting function.

Initial reset method: under normal circumstances, when the system alarm is caused by instantaneous failure, hardware reset or system power supply can be used to remove the fault in turn. If the system working storage area is powered off, the confusion is caused by unplugging the circuit board or battery undervoltage

General CNC machine tools are mainly in accordance with the pre-prepared processing procedures, automatically processed parts.

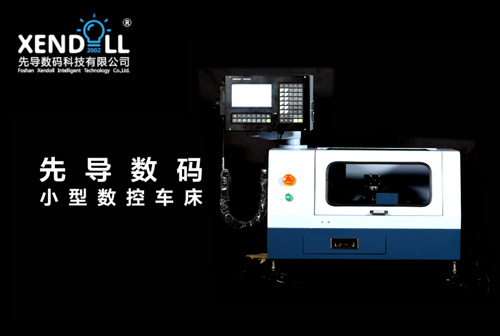

T3 CNC lathe system, ball screw, small size, high precision, stable performance, high cost performance.